Description

Simco-Ion μWire AeroBar® 5710

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

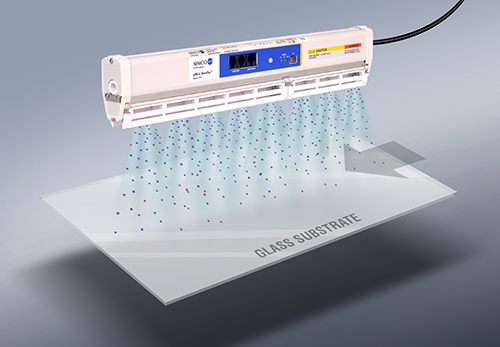

High Voltage Ionizing System Particularly Suited for Sensitive Flat Panels

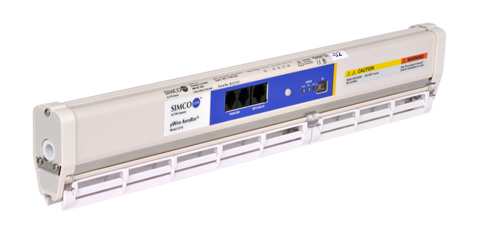

Simco-Ion’s μWire (“Microwire”) AeroBar Model 5710 is a cost-effective, high-performance ionizer specifically designed to eliminate static charge on large surface areas. The μWire AeroBar is particularly suited for sensitive flat panels where fast discharge times and low swing voltages are desired. The μWire AeroBar utilizes MicroPulse technology applied to a corona wire system for optimal performance. MicroPulse technology reduces ion recombination at the corona wire, thus increasing product efficiency and performance.

- Unique corona wire design (no emitter points)

- MicroPulse high voltage technology

- Flexible and powerful setup

Specifications

| Input Voltage | 24 VDC ±10%, 12W (max) |

|---|---|

| Discharge | <1.5 sec for ±1000V to ±100V discharge @ 30 cm (12”), 50 mm air jet spacing with min CDA 2 lpm/airjet |

| Balance | Inherently self-balancing system <±25V over the length of the bar; maintain balance setting >6 months without cleaning |

| Ion Emission | Micropulsed high voltage technology |

| Emitters | Tungsten wire, 80 micron dia. |

| Air Delivery Options | Air jet spacing at either 50 mm (recommended for target distances up to 600 mm) or 75 mm; 5710 can be ordered with straight air jets or alternately left & right angled air jets |

| Cleanliness | ISO 14644-1 Class 2 (better than Fed. Std. 209E Class 1) |

| Dimension | 3.0H x 1.3W x 15.75/19.7/25.6/29.5/35.4/39.4/45.3/49.2/55.1/ 59.1/65/68.9/74.8/78.75/84.65/88.6/94.5/98.4/ 104.3/108.25/114.15/118.1L in. (76H x 33W x 400/500/650/750/900/1000/1150/ 1250/1400/1500/1650/1750/1900/2000/2150/ 2250/2400/2500/2650/2750/2900/3000L mm) |

| Weight |

Download DataSheet for AeroBar 5710

Application Flexibility

The μWire AeroBar can be operated with the factory default settings in “plug-and-play” mode, or optimized for a specific application using

the Handheld Terminal. The bar’s ability to perform well in either a vertical or horizontal position along with the 5710 low profile height design makes it easy to install in a variety of flat-panel tool locations, including mail-slot, conveyor and load/unload cassette areas. An additional bar in a single tool can be “slaved” to a master bar to make setup and monitoring easier. Air jet spacing at either 25 mm (recommended for target distances up to 600 mm) or 50 mm distance offers optimal performance for each individual application.

CALL FOR PRICING…. 805-658-0207

Target Markets

- Flat-panel Display

- Electronics Assembly